23128 W 43rd St. Shawnee, KS 66226

913-384-0992 | info@amboxkc.com

You’ve done your research. You found your niche, mastered your marketing, and developed a great product that customers are clamoring for. Now only one question remains… how do you get it to them? Shipping products to customers can be intimidating, and shipping fragile items adds another layer of complexity. After all, sending broken products is a surefire way to damage your customer relationships. Fortunately, these tips for shipping fragile items can help you avoid breaking either.

Bag or box? Big or small? There are a variety of options out there, and what you choose depends a lot on your product. Here are some of the main ones and the best uses for each.

These are often the default choice for shipping fragile items, and with good reason. Corrugated boxes (often mistakenly referred to as cardboard boxes) provide stability and can be used with a wide variety of inner-pack options for padding. There are also a huge variety of styles available, from standard shipping boxes to fancier mailer boxes. Which style you pick is up to your product, target audience, and budget. More info about each is available on our box styles page. Corrugated boxes are particularly great for shipping multi-packs of fragile items, larger products, and products at risk of crushing.

For small fragile items, such as jewelry, bubble mailers offer decent protection without the added space of boxes. There are two main types of bubble mailers, kraft and poly. Kraft bubble mailers come with a rigid paper exterior, often in a golden brown color. This makes them more protective than the less rigid poly bubble mailer. But the polyethylene film walls of poly bubble mailers allow them to better conform to oddly shaped products, as well as making them water-resistant. In general, either option can work well for small items, but should not be used for large items or any product that needs more support.

Mailing tubes can be a good option for particularly long, moderately fragile items, such as telescopes and rolled paper items. When used to ship paper items such as posters, these shipping containers can often be used as-is and provide good crush protection. For items that need shock protection, make sure to wrap the product in bubble wrap before placing it in the mailing tube.

Inner-pack is anything that goes inside of a package to provide extra padding, support, and/or shock resistance. There are a huge variety of options available, from bubble wrap to custom inserts, and each has unique advantages.

This versatile inner-pack option provides a good amount of protection for its negligible weight. It can protect a wide variety of fragile items and is reusable so long as most of the bubbles stay intact. However, bubble wrap takes up more storage space than some of the other inner-pack options, typically coming in large rolls. Also, most bubble wrap is made of polyethylene film. This material is non-biodegradable, and while recyclable, bubble wrap often still ends up in landfills. For a more environmentally friendly option, seek out biodegradable bubble wrap, or encourage your end-users to recycle.

Packing peanuts work well to prevent items from sliding around in their container, but do not protect the surface of scratch-able items as well as bubble wrap. Generally cheaper than bubble wrap, there are two main varieties available: polystyrene peanuts, and biodegradable peanuts. Polystyrene peanuts weigh less than biodegradable peanuts, making shipping slightly cheaper. However, they are not as eco-friendly and have an electrostatic charge unless using a specifically labeled (and generally more expensive) anti-static variant. Biodegradable packing peanuts are made from starch, allowing them to naturally decompose over time or with water. They also cost more than traditional packing peanuts, so they may be less viable for those on a tight budget.

Produced by Ranpak, Geami wrap is an eco-friendly alternative to bubble wrap and is completely biodegradable and curbside recyclable. Available in both kraft and white, it is also more attractive than bubble wrap or packing peanuts. It comes in two layers: an inner tissue paper that prevents scratches and an outer honeycombed paper layer that provides shock absorption. The honeycombed layer interlocks with itself, which eliminates the need for tape. Geami wrap comes in two main types: ready rolls and unexpanded with a dispenser. The ready rolls take up extra space, like bubble wrap, but do not need any extra equipment. This makes them good for smaller operations. For larger shipping needs, dispensers can expand flat Geami wrap into a honeycomb structure onsite.

From simple foam corners to custom foam solutions, foam inserts provide great shock absorption for shipping fragile items. They come in two main types: polyurethane foam, and polyethylene foam. Polyurethane foam is softer, similar in texture to the foam used in furniture cushions. It offers excellent scratch resistance, vibration protection, and shock absorption for smaller items, like electronics. Polyethylene foam is firmer, more akin to styrofoam. It does not absorb water and provides better support for heavier items. Both foam types also come in anti-static varieties for use with electronic components.

Custom foam inserts are great for products with multiple fragile components and for instances that need good product presentation. They provide better protection than bubble wrap or packing peanuts and ensure items stay in place during transit. However, there are two primary downsides to foam inserts: cost and environmental concerns. Foam corners are a relatively inexpensive solution but only work for some products. For items that would need custom inserts, custom foam solutions are one of the more expensive inner-pack options available. Also, while both polyurethane and polyethylene foams are technically recyclable, few facilities accept them, and recycling rates remain low. But despite these concerns, foam inserts remain an excellent option for items that need shock and vibration protection or that contain multiple fragile components.

Corrugated inserts provide many of the benefits of foam inserts without the environmental cost. Like foam inserts, corrugated inserts can be crafted to hold products in exact positions for a stellar unboxing experience. These inserts present many unique opportunities for product presentation. They can be made out of kraft or white board. Designed as separate pieces or incorporated into the box. Printed or plain. And since corrugated is both recyclable and often made of recycled materials, they are one of the more eco-friendly insert options.

Like custom foam inserts, cost can be a barrier to using corrugated inserts. In general, custom corrugated inserts are likely within your budget if your e-commerce business is large enough that you are looking into or already using custom boxes, rather than stock or post office options. For small operations, like Etsy stores, bubble wrap, Geami wrap, or packing peanuts may be more affordable options. But for medium to large operations, or for instances where product presentation is key (such as subscription boxes and luxury items), corrugated inserts remain an excellent eco-friendly packaging solution.

Well-taped packaging can mean the difference between a safe shipment or a damaged product. Bubble mailers are typically self-sealing, but both mailing tubes and corrugated boxes need to be taped.

The type of tape you use is important to keep your items safe. Do not use duct tape or masking tape when packaging items for shipping. Instead, use pressure-activated plastic tape (commonly referred to as packing tape), or water-activated tape. Pressure-activated plastic tape is inexpensive and provides a good seal, and is best suited for smaller operations. It can also be customized in different colors and custom prints. Water-activated tape bonds better with corrugated, making it both tamper-resistant and more secure. It can be applied quickly and can be branded with different colors and prints. However, this type of tape requires the purchase of an electronic dispenser, making it better suited to medium to large shipping needs.

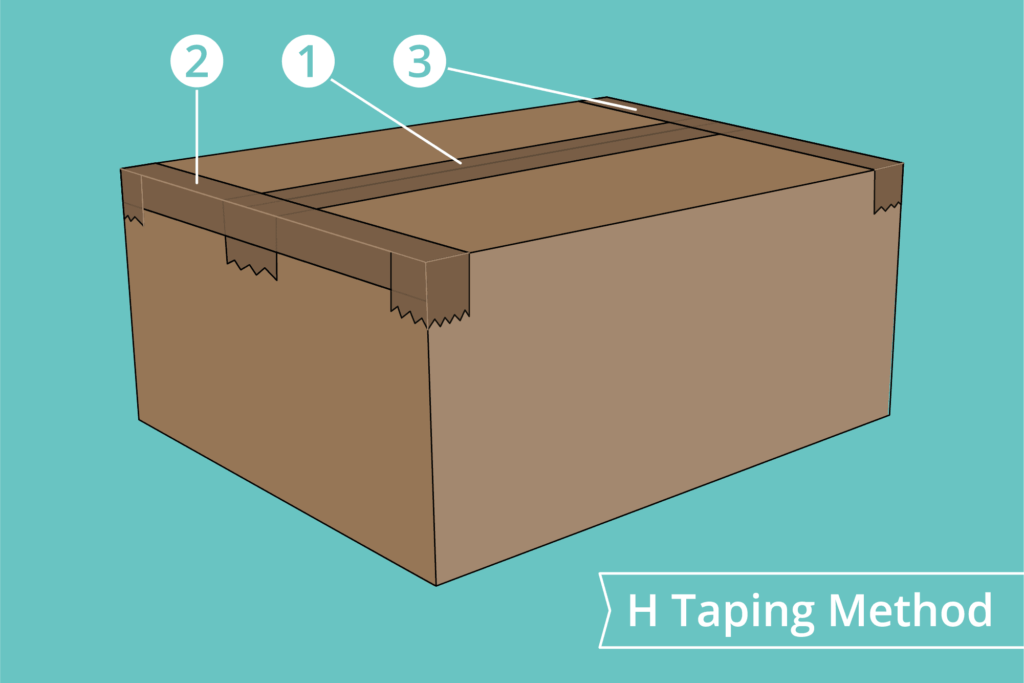

For mailing tubes, secure the ends of the tube with tape after closing them. This helps prevent them from popping open during shipment. For standard shipping boxes, use the H-taping method on the top and bottom of the box. To do this, tape all seams on the box, making an “H” shape.

Mailer boxes that don’t have locking tabs and are shipping without an outer box also need to be taped. For mailer boxes with a front tuck, add a wafer seal or tape along the bottom of the front flap. Or, for mailer boxes with a top tuck, add a wafer seal or tape to the top front of the box.

Double boxing adds an extra layer of protection and can be especially helpful for shipping expensive fragile items. To double box, measure your original package and add an extra 6 inches to the length, width, and depth. This will give you the size you need for your outer box to have 3 inches of inner-pack on all sides. Prepare your first box as normal, then place around 3 inches of inner-pack in the bottom of your outer box (large bubble-wrap, packing peanuts, or foam corners work well). Center your original packaging in the box and fill all sides with more inner-pack. Continue adding inner-pack until your original packaging is covered and the outer box is full. Then, secure the outer box using the H-taping method.

Spending a small fortune on inner-pack? Are shipping costs killing your bottom line? Items shifting in the box? Your shipping packaging may not be correctly sized for your product. Packages for shipping fragile items should be fitted to the product they contain, with around 2-3 inches leftover on all sides for inner-pack. To find out how big of a box you need for your item, measure the length, width, and depth of your product, then add 4-6 inches to each measurement. For items that will be double boxed, 4 inches generally works, while 6 inches should be used if the item will only be single-boxed. If you are packing multiple items, add an extra 2 inches of space between each item for inner-pack.

If you are running a small business or need to order packaging on a case-by-case basis (small Etsy shops, eBay listings, startups), purchasing stock boxes is a simple and economical way to get packaging in the sizes you need. Most post offices will offer a variety of box and inner-pack options, and both FedEx and UPS even offer packaging services. To order a large amount of the same stock box, going through a box manufacturer is often a more economical option. You can view our stock box offerings here.

The best way to get boxes that are correctly sized for your product is to order custom boxes. A reputable box company will be able to help you determine the best packaging style, inner-pack, and box size for shipping fragile items. Many can even help with warehousing and fulfillment as well. At American Box, we offer a wide variety of packaging services, including custom packaging and insert design, fulfillment, warehousing, and vendor-managed inventory. We would love to help you find the best solution for your fragile packaging needs, so you can stop worrying about packaging and get back to managing your business. To get started, schedule a free design consultation with us today!