23128 W 43rd St. Shawnee, KS 66226

913-384-0992 | info@amboxkc.com

As Kansas City’s premiere custom packaging partner, we work with customers to develop the best packaging solutions for their needs. They ask us about the differences between corrugated board grades and how to choose the right corrugate for your product.

Using the correct corrugated board grade affects everything from the level of protection the box offers to shipping costs and branding options. So making the right selection for the job is essential.

In this post, we make updates to a previous blog on the topic and cover the key considerations you need to make an informed decision about corrugated board grades.

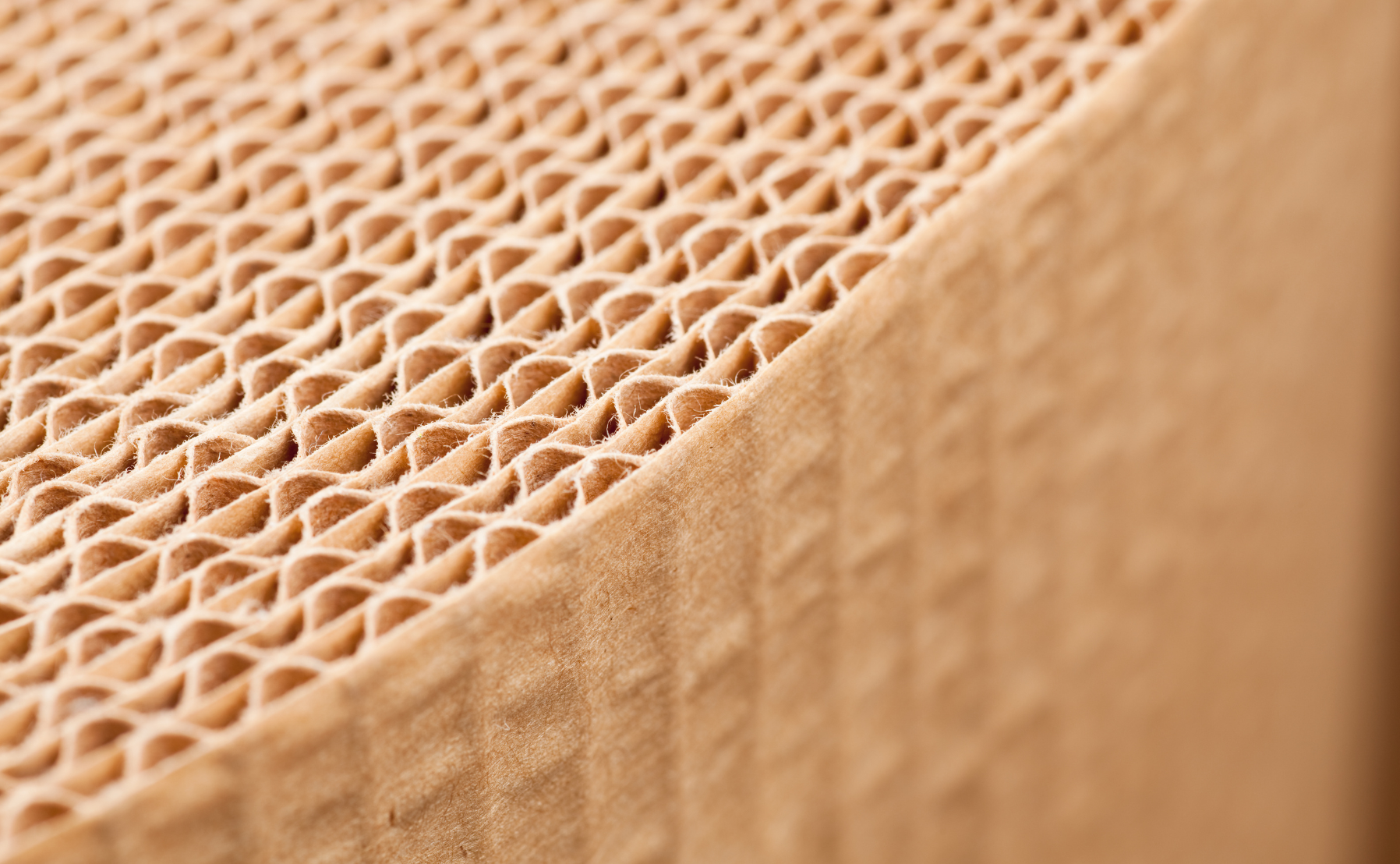

Corrugated board grades refer to the different strength, thickness and durability levels of the corrugate used in packaging and shipping. Three main factors – flute size, number of walls, and strength ratings – determine these grades.

You may be thinking, “That all sounds important but what is a flute? And how do you select the right number of walls?” That’s where American Box Company can help. We’re here to guide you through the process of selecting the best solution for your product and shipping goals.

The flute is the wavy layer inside the board. You’ll see it sandwiched between two linerboards made of Kraft or Test paper. The flute gives the corrugated board its durability and protection. The arched flute shape evenly distributes weight for better stacking strength, while the air pockets provide cushioning to protect against impact. Therefore, the box stays intact during shipping due to the fluting’s rigid structure.

Each flute size provides a different balance of strength, thickness and printability. The most common flut types in corrugated board are:

Wall construction refers to the number of corrugated layers in the board. Corrugated board comes in single-wall, double-wall, and triple-wall constructions.

Mix and match flute types with double- and triple-wall boards to balance strength, cushioning and printability. For example, B-Flute + E-Flute can be combined for durability with a smooth printing surface.

You may have heard of the Mullen test or the Edge Crush Test (ECT). These tests determine how much weight a box can handle.

The Mullen test measures the burst strength of a box or how much pressure it can withstand before ruptures or tears. The results are measured in pounds per square inch (psi). The ECT measures stacking strength. It looks at how much weight the edge of the box can stand without collapsing. These results are also given in psi. The team at American Box Company can help you select a box type with the correct strength rating for your packaging needs.

It’s important to understand corrugated board grades because they directly impact the durability, cost, and protection of your shipment, which can have far-reaching effects on your business.

When you choose the best corrugated box for your packaging needs, you:

Understanding corrugated board grades allows you to make the best packaging decisions for your business needs and American Box Company is here to help. Our focus has always been on providing the highest standard of service to every customer, including guiding you through the board grade process.

From custom packaging solutions to heavy-duty shipping boxes, we have the experience to help you determine your ideal corrugated board grade.

Contact us today to learn how we can take your packaging and displays to the next level.