23128 W 43rd St. Shawnee, KS 66226

913-384-0992 | info@amboxkc.com

When ordering packaging, you will likely be asked about the weight of your product. You may even be asked if you have a specific corrugated flute you would prefer for your packaging. Corrugated board, often mistakenly called cardboard, comes in a variety of board grades, and these questions help designers determine the best one for your packaging. But what are they, and why do they matter?

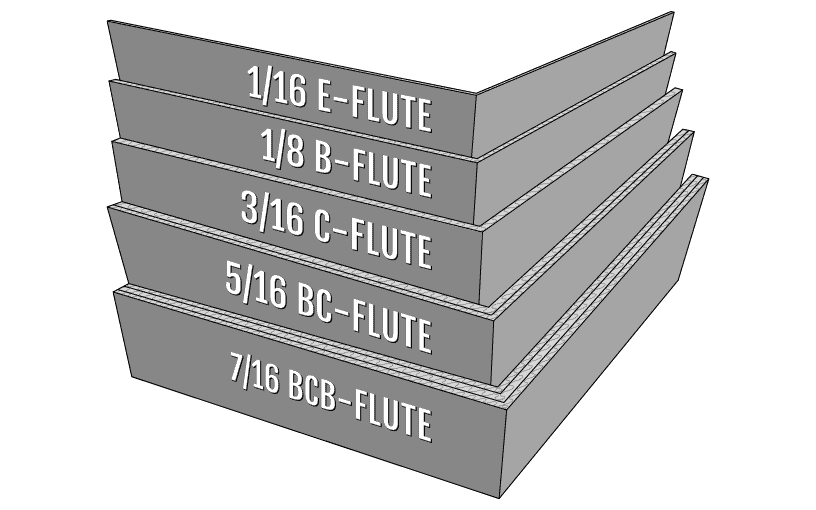

If you look at the edge of a sheet of corrugated, you’ll see that the middle section is made of wave-shaped arches. These arches are called flutes, and they are the reason corrugated is much stronger than the sum of the thin material layers it’s made of. The size of these arches effect the board’s crush resistance, print quality, cushioning, and more.

Manufacturers use a lettering system to show the size of a board’s flute. In general smaller, more tightly spaced flutes provide better crush resistance and print quality. Whereas larger flutes offer better compression and cushioning.

Flutes can also be combined to create double or triple wall boards which combine the attributes of both flute types. Questions about product weight, desired print, and intended packaging use all help designers determine the best flute type for your project

A flute is the thickest of the common flutes and the first to be invented and named. It works well for shipping boxes and packaging fragile items, as it provides excellent cushioning and good stacking strength. However, it is not ideal for boxes that need print.

An excellent choice for shipping boxes, C flute offers good stacking strength and cushioning. It also provides a decent printing surface for basic print. C flute is the most common flute, making up around 80% of corrugated packaging.

B flute offers good print quality while still providing decent stacking strength and cushioning. It has good crush and puncture resistance. It is also able to fold into smaller and more intricate designs than C or A flute. B flute is an excellent choice for e-commerce mailers, POP displays, and folding inserts.

E flute has excellent print quality and crush resistance. Its thinner board size helps reduce overall box dimensions, and allows it to be used for highly intricate or mini packaging. E flute is a good choice for smaller retail packaging.

F flute offers exceptional print quality and crush resistance. Its thin board size and high flute count make for more rigid cartons with a small footprint. This makes it an excellent choice for cosmetic and fast food packaging.

Another facet of board grades are the board’s test. Corrugated manufacturers use two main testing types to determine a board’s strength: Mullen and ECT. Both describe the overall strength of the board, but each measures a different feature. For both tests, the higher the number, the stronger the board.

Developed in 1887, The Mullen Test measures how much pressure a piece of corrugated can withstand before bursting. It is good for testing boxes that will be handled individually and potentially roughly.

The Edge Crush Test (ECT) measures how much pressure a piece of corrugated board can withstand when standing on edge. It is a more recent testing method than the Mullen test, but has quickly become the more commonly used testing method. This is because many items are now shipped on pallets and the ECT is ideal for testing how boxes will perform when palletized. Boards graded using the ECT also only need around 90% of the weight to score a similar score to boards graded using the Mullen Test.

In packaging, having the wrong board grade for the job could mean damaged product, inflated board costs, difficult assembly, or poor print quality. That’s why at American Box, we take the time to ask you questions about your product’s weight, packaging print type and any other questions we feel are necessary to make sure you end up with the best packaging solution for your needs.

Have more questions about board grades, packaging, or anything else? Feel free to contact us today!