23128 W 43rd St. Shawnee, KS 66226

913-384-0992 | info@amboxkc.com

The cardboard box: a term almost as ubiquitous as the simple brown boxes it refers to. Except… those brown boxes aren’t actually cardboard. When speaking with a packaging manufacturer you will hear a lot of terms thrown around — but what do they actually mean? And what is the difference between cardboard and corrugated?

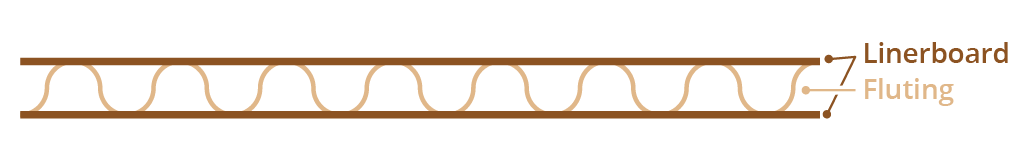

When most people use the term “cardboard box”, what they are actually referring to is a corrugated box. Corrugated board is typically made of at least three layers: two outer layers of linerboard, and an inner layer of fluted (wavy) medium. Cardboard only has one layer: a thin, stiff pasteboard. It is used to make playing cards and signs. The structure of corrugated board makes corrugated boxes much stronger than the sum of the individual layers. However, a box made of actual cardboard would offer little protection.

The strength and versatility of corrugated board makes it an excellent material for a variety of uses. It can form anything from simple shipping containers to complex POP displays. And — by switching up the flute type and linerboard used — it can be thick and cushiony or thin and precise, white or kraft.

The arrangement of the linerboard and fluting enables a wide variety of different types of corrugated board. Some of the most common include:

Corrugated is also naturally recyclable. In fact in 2020, people and companies recycled 88.8% of old corrugated containers. Most corrugated boxes also contain recycled material, making corrugated an eco-friendly packaging solution.

From intricate retail displays to simple brown shipping boxes, corrugated board has become a part of our everyday lives. And by understanding the terminology — you can make sure that the next time you order packaging your manufacturer will know exactly what you want.